In a world fighting against the waste of resources, banding offers a forward-looking solution. Discover how a small adjustment in your packaging can save up to 80% of materials, reduce costs, and promote sustainability. Your company can make a difference.

Minimal Use of Materials

A banding strap can be used in various ways. Whether it's for bundling, labeling, sealing, or a combination of these applications, it contributes to more sustainable packaging in almost all cases. Moreover, banding makes many additional packaging elements unnecessary. Think of rubber bands, clips, adhesive tape, or self-adhesive labels. Less is more!

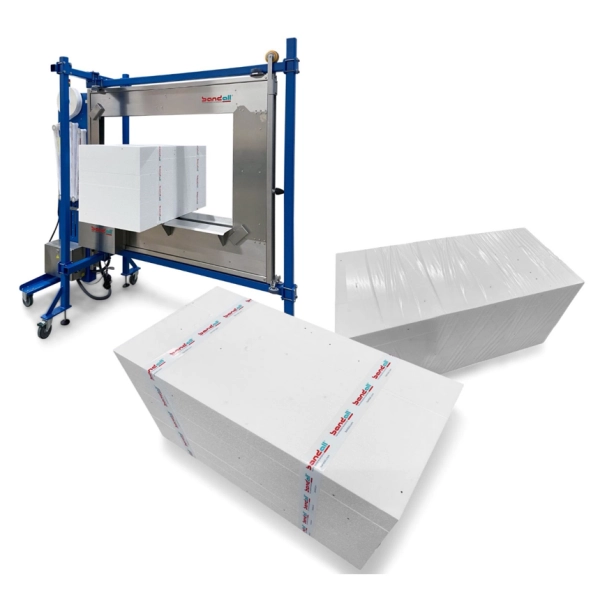

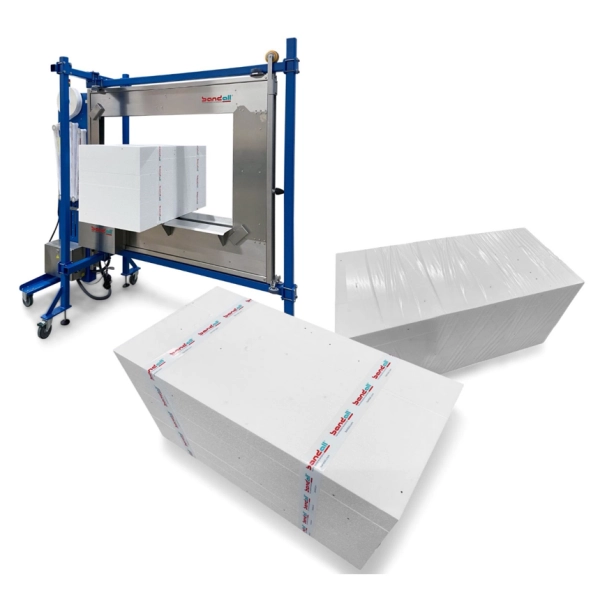

A prime example is the EPS industry. EPS boards – often intended for the construction industry or industrial use – are frequently completely wrapped in shrink film. But is that really necessary? A Danish manufacturer was able to save 74.7% of material by switching to banding. And in other industries, banding renders outer cartons, plastic bags, and shrink film redundant.

Concrete Practical Examples

1. Laundry industry: Save 92.4%

2, EPS industry: Save 74.7%

3. Mats and Carpets: Save 75%

Less Waste Thanks to Smart Printing Technology

Printing variable information during the banding process also reduces waste. A small change, such as in the product description or nutritional values, no longer automatically means that you have to throw away all your existing labels. And that's a significant advantage of printing during the banding process. It makes your packaging process more flexible and thus more sustainable.

Want to learn more?

Take the step towards a more sustainable future now and learn more about our banding solutions. Visit our website and transform your packaging concept.